Following wheels and tyres, the next priorities in modifying your car to make it perform better are suspension and brakes, again before you touch the engine. You will find that with more cornering power at your disposal, your point-to-point times will be quicker anyway, as cornering speeds will begin to be limited only by visibility, by the need to retain the vital ability to stop safely within the distance you can see to be clear.

You will also find that a car with better suspension control is more comfortable to ride in as it does not roll so much in corners or give that uncomfortable wallowing sensation when driving on bumpy roads. Again, you can go too far. A car that is made too stiff in its suspension settings can be most uncomfortable. It is jiggly, you can leave the seat over big bumps and you will have less traction in bumpy corners as the car takes off over undulations. And it is skittish in the wet.

Ride and handling are thus a compromise, and VW in fact set a very high standard with the stock fuel-injected cars. The Mk1 cars are slightly under-damped and prone to rock-roll slightly in fast bumpy bends but the Mk2 car is superb straight out of the box. That is not to say that the Mk2 GTI cannot be improved. Far from it. To understand fully how the various suspension tweaks improve a car’s handling, let us look at the forces acting on a car when it is driven on the road or track.

Roll: a by-product of cornering, roll takes place along the longitudinal axis and in a softly sprung vehicle tries to lean the car excessively to the detriment of comfort and cornering ability. The more a car rolls, the greater the slip angles of the tyres and the less of the useful tread area is doing work. The primary component that will reduce this condition is the anti-roll bar, or swaybar as it is called in America.

Pitch: occurs on the transverse rotational axis and causes a car to dive under braking or squat under acceleration. In the absence of anti-dive, anti-squat geometry being designed into the suspension by angling the lower arm locating points, the springs and dampers play the major role in reducing the amount of pitch. Good progressive suspension prevents harsh oscillations.

Yaw: a force that provokes body motion around the vertical axis, yaw affects all the suspension components. In an ideal situation, a vehicle’s suspension should provide completely neutral handling, but most cars are designed to provide mild understeer which allows the front of the car to go wide in corners. This is a safe characteristic to keep the average driver from getting into trouble especially when braking or suddenly decelerating in a bend where a neutral vehicle could then move into oversteer and perhaps spin. If you stiffen just one end of the car at a time, you can induce severe yaw conditions; stiffening the rear induces oversteer while stiffening the front only creates understeer. Suspension development is very much a question of balance.

Modifications: to save customers a lot of time and trouble, aftermarket suspension manufacturers have developed kits for various cars providing just uprated springs, or dampers, or matching springs and dampers (which is better), as well as upgraded anti-roll bar kits to be used with the stock suspension or in conjunction with the spring and damper kits. The European manufacturers, like Bilstein, Koni, Sachs, Spax and others, favour the spring and damper kit approach while the Americans, with a more conversion-orientated custom-car background, tend to go the whole hog with upgraded anti-roll bar kits and better quality locating bushes as well.

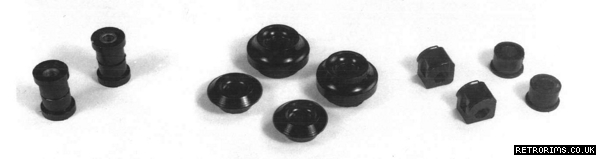

Bushes locate suspension components to prevent metal-to-metal contact and provide isolation from road shock and noise. They are used in all moving components in the suspension and steering in modern cars and if a manufacturer is over-generous with these rubber bushes, the car can feel rubbery in its handling and ride. Too much lateral movement in suspension bushes does not help accurate suspension location and makes a car feel woolly in corners. Conversely, the metal or metal and nylon rose joints used in racing suspension are too hard and direct for road use and would destroy themselves in short order. Upgraded high-quality road-car bushes made of polyurethane, like the AutoTech ones, will keep the suspension components in check while maintaining adequate comfort. Polyurethane steering bushes will sharpen up the GTI’s steering, which has a slightly dead feel about the straight-ahead position.

AutoTech in California are US distributors for Hor Technologie parts. Hor are an original-equipment manufacturer who supply suspension, exhaust and other components to German car makers like BMW and VAG but who do their own range of aftermarket parts too. AutoTech are also agents for the excellent Japanese-made Tokico adjustable shock absorbers which match up well with Hor springs. The UK agents are Steiner Engineering.

Amongst the European suspension manufacturers, you will find that each of the kits you can buy has different characteristics and so will please customers looking for different kinds of performance. The Koni suspension has adjust-ability of damper settings as its strength. You can raise and lower the rear spring pans to adjust ride height and the dampers can be tailored from soft to fairly hard settings if you want to commute in the week and then do club events at the weekend. Koni now have another damper design with a semi-active electronically controlled system – the normal kit is user-adjustable from the shock towers.

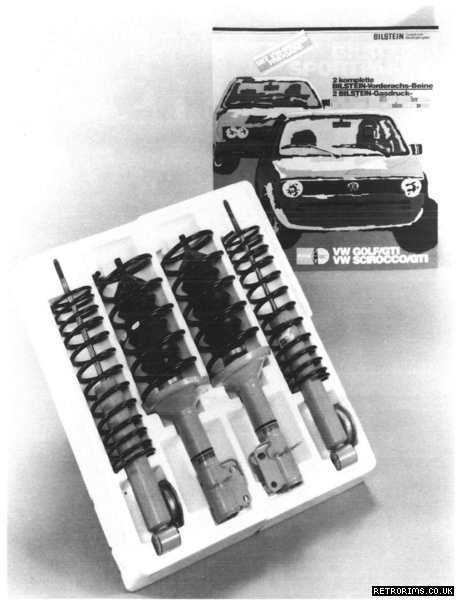

The Bilstein Sportpak was the first kit on the market for the original GTI and gives a firm ride but brilliant handling. It may be too firm for those who live near less-than-smooth roads, and the gas filled dampers are not adjustable. The kit for the Mk2 is more supple and was the last of the three Europeans to appear.

While Sachs were last on the scene with the Mk1 GTI kit, they were at the head of the queue with the Mk2. Their Mk1 kit strikes a good comfort/handling balance for most people but may still be too soft for really press-on drivers. The Sachs Mk2 kit, on the other hand, is well-nigh perfect, with very little comfort lost over the standard suspension, and it also gives very progressive handling on the limit. All these kits lower the ride height by about an inch which helps stability.

It is not unusual for road testers in different countries to form slightly different opinions of a given car, especially in ride and handling terms. There are several reasons for this, not least of which is that suspension settings are in fact often tailored to the country of destination. The Americans like a softer-riding car despite the good quality of their roads and enthusiasts then complain that the car does not handle properly. Grip and tyre noise are affected by the content of the road surface and this varies from country to country. Thus, a Pirelli P6 manufactured in the UK for local use may turn out to be different from one made at Pirelli’s German factory or indeed one made in the home market of Italy. Suspension, wheel and tyre tuning must thus be done for local conditions and, on that score, companies like Automotive Performance Systems (APS) in California specify different damper settings for their Bilstein kits from those that you would find in Europe. By the same token, a German-bought set might prove a touch hard for use in the LK. Caveat emptor…

Anti-roll bars: the suspension design of the Golf and Golf-derived cars allows the inside rear wheel to pick up under hard cornering. While this is safe in practice, it is indicative of a very severe roll attitude. The solution is to increase the roll stiffness of the chassis without affecting suspension travel and thus ride comfort adversely. The AutoTech front anti-roll bar is a direct replacement for the factory original and comes with all the fitting hardware. The rear factory bar is part of the torsion beam assembly and thus upgrading it means adding an additional external bar. Such an external bar will have different pivot points from the torsion beam and, once the beam is deflected, this would cause the anti-roll bar to push or pull the end of the beam out of alignment. AutoTech’s rear bars use a clever sliding end design to allow the beam to move properly and yet be usefully acted on by the anti-roll bar.

Stressbars: when a car is cornered hard, the forces produced by the act of the tyres gripping the road transmit high loadings back through the suspension to the monocoque bodyshell. Even though the mounting points are reinforced, the shell still deflects. A hatchback car with its large rear aperture is less rigid than a saloon, a convertible potentially even worse. When the shell deflects, it affects the suspension geometry, the accuracy of which is vital for good handling and grip. The Golf Mk1 shell is much less rigid than the Mk2 and the Cabriolet even weaker despite substantial bracing to compensate for the loss of the roof. The Cabriolet also has a higher centre of gravity and so benefits even more from suspension bracing and uprating.

The weakest point of the Mk1 chassis is the lower front and the car benefits tremendously from a lower brace to stabilize the lower wishbone mountings. This has been done in more than one way by various manufacturers. The normal after-market European brace is a single bar which attaches to the front joints of both lower wishbones via the retaining bolts and then has two further bolts which attach it to the floorpan. Realising the weakness of the chassis, the factory developed a similar brace for the Scirocco 16Y and this used a wholly tubular design with four mounting points which did the same job. Techtonics market a brace for the Mk1 cars which they admit is a direct copy of this.

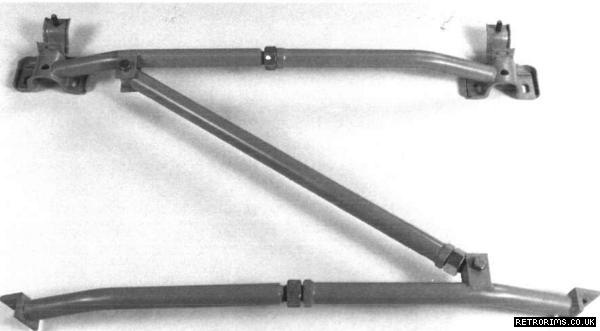

The most comprehensive lower strut brace is the triangulated, fully adjustable one from AutoTech which is really a subframe. This connects the front and rear mounting points of the lower wishbones for maximum bracing and is then triangulated between front and rear bars. It is fully adjustable to take in the production tolerances of individual cars.

A lower brace is more effective than an upper one on all Mk1 floorpan cars, i.e. Golf 1, Scirocco 1 and 2 and Jetta, but an upper shock tower brace is icing on the cake. The improvement in turn-in and cornering stability is instantly felt with the lower brace and steering becomes more positive. In the long term, the continuous loadings on the suspension strut towers weaken a car’s structure. The upper stressbar helps to prevent this fatigue and staves off squeaks and rattles in higher-mileage cars. The Mk2 has a rigid front subframe from the factory- and only needs a top stressbar.

As the rear torsion beam twists, so the loadings are transmitted to the bodyshell. A simple adjustable bar can be used to join the tops of the towers and this is easily removed when you need to use the car’s full luggage earning capacity. For more serious high-speed work, a multi-link triangulated set up is available from APS (Neuspeed) which has permanent fixtures in the bodywork via aircraft type Nutserts. The crossbrace, however, can still be removed.

©Ian Kuah. This article was published with explicit permission from author Ian Kuah